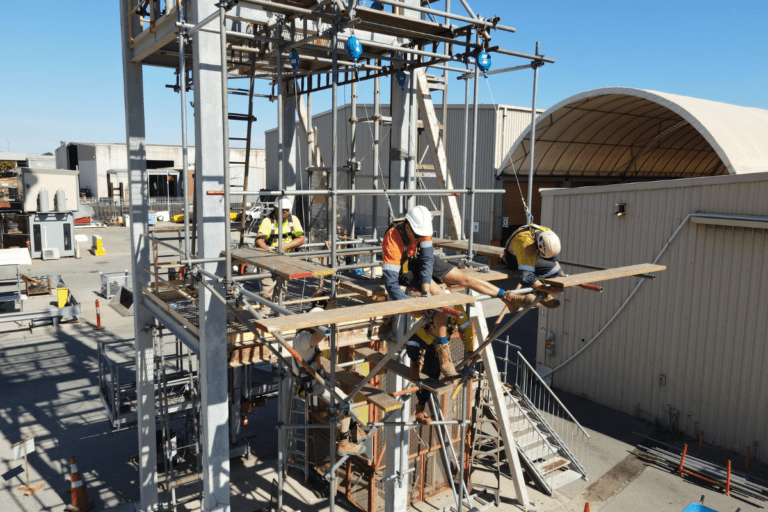

Working at heights remains one of the most high-risk activities in Australian workplaces. Even a fall from a low level can result in serious injury or death, which is why strong safety systems, correct equipment use, and ongoing training are critical.

Recent updates to key Australian Standards, particularly AS 5532 and AS/NZS 1891.4:2025 ,reflect changes in industry best practice for fall-arrest equipment, anchor systems, and inspection procedures.

At Saferight, we ensure all our training, equipment, and procedures are aligned with the latest Work Health and Safety (WHS) legislation, the WA Code of Practice – Working at Heights, and relevant Australian Standards, so you can work safely and confidently.

The Legal Framework: WHS Laws and Codes of Practice

In Western Australia, the following documents set the legal and best-practice foundation for working safely at heights:

- Work Health and Safety Act 2020 (WA) – establishes the legal duty to ensure, so far as is reasonably practicable, the health and safety of workers.

- WHS (General) Regulations 2022 – require fall risks to be eliminated or minimised and mandate that equipment be used in accordance with the manufacturer’s instructions and recommendations for safe use.

- WA Code of Practice – Working at Heights – provides practical guidance on how to comply with legal duties, including planning, risk assessment, fall prevention, fall arrest, emergency response, training, and supervision requirements.

Australian Standards, such as AS/NZS 1891.4, are not legislation but provide valuable advisory guidance on best practice. They should be read and applied alongside WHS legislation, manufacturer instructions, and the Code of Practice — not instead of them.

Key Updates in 2025

AS 5532 – Single-Point Anchor Devices

- Real-world testing: Anchors must now be tested on the actual roof or structure materials they will be installed on, improving real-world safety performance.

- Enhanced fall-protection performance: Testing methods now account for how anchors absorb and dissipate energy during a fall event.

- Wider application range: Broader support for installation on various roof and substrate types.

- Clearer installation requirements: Reduces risks such as swing falls and excessive free-fall distances.

AS/NZS 1891.4:2025 – Selection, Use & Maintenance of Fall-Arrest Systems

- Up-to-date best practice: Guidance now reflects modern fall-arrest equipment and current industry practices.

- Improved inspection and maintenance requirements: Ensures systems remain safe and effective throughout their service life.

- Better training alignment: Helps ensure users are properly trained in the safe use, care, and limitations of fall-arrest equipment.

What Hasn’t Changed

- Legal obligations: PCBUs (employers) and workers must still manage fall risks “so far as is reasonably practicable” under the WHS Act and Regulations.

- Manufacturer instructions take precedence: All equipment must always be used according to manufacturer instructions. These are mandatory and take priority over advisory guidance.

- Risk control hierarchy: Eliminating the need to work at height remains the highest level of control. Where this is not possible, fall prevention, restraint systems, and fall-arrest systems should be implemented in order of effectiveness.

- Safe Work Method Statements (SWMS): Still required for any work involving a risk of a fall from 2 m or more.