Understanding the differences between slewing and non-slewing mobile cranes is essential for choosing the right course and equipment for your needs. At Saferight, we offer a range of mobile crane courses designed to equip you with the necessary skills and knowledge to operate these cranes safely and effectively. In this blog, we will explore the differences between slewing and non-slewing cranes, provide an overview of our mobile crane courses, and guide you on how to enrol.

Introduction to Mobile Crane Courses

Mobile crane courses are essential for anyone looking to work in industries that require heavy lifting and material handling. Mobile cranes are versatile pieces of equipment used in various industries for lifting and moving heavy loads. They are broadly classified into slewing and non-slewing cranes based on their boom rotation capabilities. Saferight offers comprehensive training for both types, ensuring you are well-prepared to operate these cranes in real-world scenarios.

Understanding Non-Slewing Cranes

What is a Non-Slewing Crane?

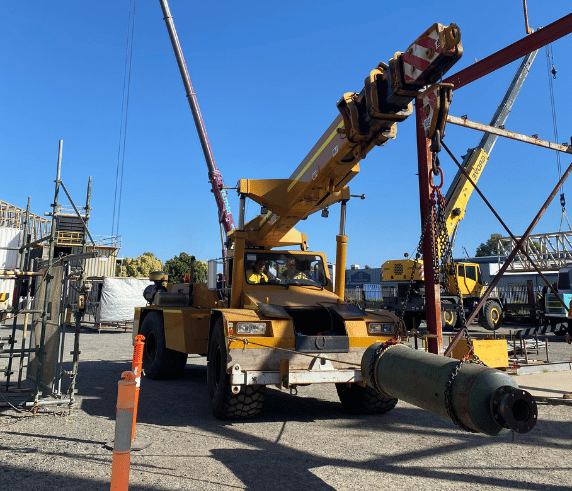

A non-slewing crane, also known as a non-rotating or fixed-base crane, is characterised by its inability to rotate the boom around a central axis. Unlike slewing cranes, non-slewing cranes have a fixed boom that can only move up and down, making them simpler and often more cost-effective for specific lifting tasks.

Key Features of Non-Slewing Cranes

Fixed Boom

The boom in non-slewing cranes is fixed in one direction and can only be raised or lowered. This limited range of motion makes them ideal for applications where lifting needs are straightforward and within a confined area.

Stability

Non-slewing cranes are typically more stable than slewing cranes because their design reduces the risk of tipping over. The fixed boom and limited movement contribute to their stability, making them suitable for use on uneven or rough terrain.

Compact Design

These cranes are often more compact and easier to transport compared to their slewing counterparts. Their simpler design means fewer components, which can translate to lower maintenance costs and easier operation.

Applications

Non-slewing cranes are commonly used in industries such as construction, agriculture, and logistics. They are ideal for tasks like loading and unloading materials, lifting heavy objects within a restricted area, and other jobs that don’t require the boom to rotate.

Cost-Effectiveness

Due to their simpler mechanism and limited range of motion, non-slewing cranes are often less expensive to purchase and maintain. This makes them a cost-effective choice for businesses that need reliable lifting solutions without the added complexity of a slewing crane.

What Are Non-Slewing Cranes Used For?

Material Handling

Non-slewing mobile cranes are frequently used for loading and unloading materials. Their ability to pick up loads and carry them to a different location makes them invaluable in warehouses, distribution centres, and construction sites.

Assembly and Installation

These cranes are often employed in assembly and installation tasks. For example, they can lift and position heavy machinery, structural components, or large equipment parts with precision.

Maintenance and Repair

In industrial settings, non-slewing mobile cranes assist in maintenance and repair activities. They can lift and transport parts that need servicing, reducing downtime and improving efficiency.

Transporting Loads

Their primary function as pick-and-carry cranes means they are used to move loads from one part of a job site to another. This is especially useful in scenarios where other means of transport are impractical.

Non-Slewing Crane Courses

CN Non-Slewing Mobile Crane

Course Overview

The CN Non-Slewing Mobile Crane course covers the operation of non-slewing cranes in various work environments. This course is ideal for those who need to operate cranes for material handling and other lifting tasks in construction and industrial settings.

Units of Competency

- Conduct non-slewing crane operations

- Apply site safety procedures

- Perform routine checks and maintenance

Understanding Slewing Cranes

What is a Slewing Crane?

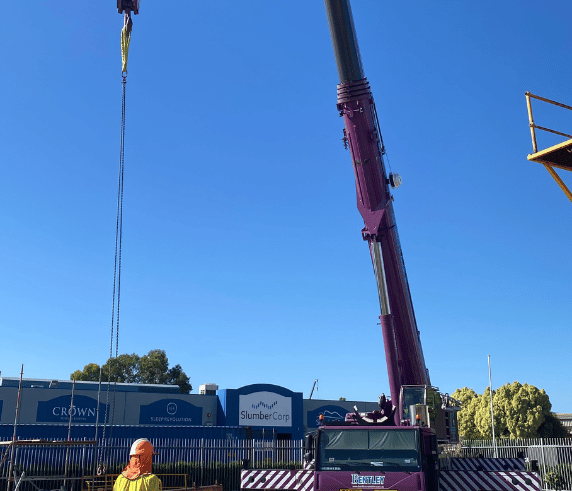

Slewing cranes, also known as rotating cranes, can rotate the boom around a central axis, allowing for a full 360-degree movement. This capability provides greater flexibility and reach compared to non-slewing cranes.

Key Features of Slewing Cranes

Rotating Boom

The defining feature of a slewing crane is its rotating boom. This boom can turn around a central axis, allowing the operator to lift and place loads anywhere within the crane’s radius without needing to reposition the entire crane.

Versatility

Slewing cranes are highly versatile and can be used in a wide range of applications, including construction, shipping, and heavy industry. Their ability to rotate makes them ideal for tasks that require precise positioning of materials over a large area.

Extended Reach

The rotating boom of a slewing crane can extend horizontally and vertically, providing a wide range of motion. This makes slewing cranes suitable for complex lifting operations where obstacles need to be navigated.

Complexity and Control

Due to their advanced rotating mechanism, slewing cranes are more complex and require sophisticated control systems. Operators need to be well-trained to handle the crane’s movements safely and effectively.

Applications

Slewing cranes are commonly used on construction sites, in shipyards, and for infrastructure projects. They are essential for tasks that involve lifting heavy materials to high elevations or moving them horizontally across a job site.

Cost and Maintenance

While slewing cranes offer greater flexibility and reach, they are typically more expensive to purchase and maintain compared to non-slewing cranes. Their complexity and additional moving parts require regular maintenance and skilled operation.

What Are Slewing Mobile Cranes Used For?

Construction Industry

High-Rise Building Construction

Slewing mobile cranes are extensively used in constructing skyscrapers and other tall structures. Their ability to manoeuvre heavy materials to significant heights is invaluable.

Bridge Construction

These cranes are essential for lifting and positioning large bridge segments, facilitating the construction of both small and large-scale bridges.

Residential and Commercial Projects

From small residential buildings to large commercial complexes, slewing mobile cranes are indispensable for various lifting tasks, such as placing steel beams, concrete panels, and prefabricated components.

Industrial Applications

Manufacturing Plants

In manufacturing settings, slewing mobile cranes are used to lift and move heavy machinery and equipment, ensuring efficient production processes.

Power Plants

These cranes are vital for installing and maintaining heavy components like turbines, generators, and other machinery in power plants, including nuclear, thermal, and hydroelectric facilities.

Infrastructure Development

Road and Highway Construction

Slewing mobile cranes play a significant role in the construction and maintenance of roads and highways, assisting in the placement of heavy barriers, signage, and bridge components.

Railway Projects

These cranes are used for laying tracks, positioning large segments of railway infrastructure, and maintenance tasks.

Marine and Offshore Industries

Shipbuilding

In shipyards, slewing mobile cranes are essential for assembling and repairing ships, handling heavy parts like hull sections, engines, and other components.

Offshore Drilling

These cranes are used on offshore platforms to handle equipment and materials needed for drilling operations.

Mining and Quarrying

Material Handling

In mining operations, slewing mobile cranes are used to move heavy equipment, load materials onto transport vehicles, and facilitate the maintenance of large machinery.

Slewing Crane Courses

CO Slewing Mobile Crane

Course Overview

The CO Slewing Mobile Crane course provides comprehensive training on operating slewing cranes with a capacity of over 100 tonnes. This course is designed for those involved in large-scale lifting operations.

Units of Competency

- Plan and prepare for slewing crane operations

- Operate a slewing crane safely and effectively

- Perform maintenance and inspection

C1 Slewing Mobile Crane

Course Overview

The C1 Slewing Mobile Crane course focuses on cranes with a capacity of up to 100 tonnes. This training is essential for operators working in construction and industrial projects.

Units of Competency

- Conduct slewing crane operations

- Apply risk management procedures

- Perform routine checks and maintenance

C6 Slewing Mobile Crane

Course Overview

The C6 Slewing Mobile Crane course is tailored for cranes with a capacity of up to 60 tonnes. It covers all aspects of crane operation, from planning to execution.

Units of Competency

- Conduct slewing crane operations

- Apply workplace safety procedures

- Perform equipment checks and maintenance

Why Choose Saferight’s Mobile Crane Courses?

Career Advancement

Completing a mobile crane course at Saferight can significantly boost your career prospects. The skills and knowledge gained are highly valued in the industry, and employers often seek individuals with these certifications for key roles.

Practical Training

Our courses provide hands-on training with real-life scenarios, ensuring that participants are well-prepared to handle actual crane operations. The practical approach helps build confidence and competence in dealing with high-pressure situations.

Industry Recognition

Saferight’s courses are widely recognised within the industry, making them a valuable addition to your professional credentials. Our certifications demonstrate your commitment to safety and your ability to manage crane operations effectively.

How to Enrol

Enrolling in Saferight’s mobile crane courses is straightforward. You can choose to enrol in any of the specific courses mentioned above based on your needs and career goals.

Enrol in Mobile Crane Courses

Explore our full range of mobile crane courses and take the first step towards mastering crane operations. Enhance your skills, boost your career, and ensure safety in your workplace by enrolling in Saferight’s comprehensive training programs.

Mobile Crane Conclusion

In the realm of heavy lifting and material handling, both slewing and non-slewing cranes play crucial roles, each with its unique advantages. Slewing cranes, with their ability to rotate a full 360 degrees, offer unparalleled flexibility and precision, making them ideal for complex construction projects and tight spaces where precise positioning is critical. Non-slewing cranes excel in their simplicity, mobility, and compact design, making them the go-to solution for straightforward lifting and transport tasks.

By understanding the distinct benefits of slewing and non-slewing cranes, industry professionals can select the most appropriate equipment for their specific needs. Leverage the efficiency and capabilities of each type to optimise operations, improve efficiency, and ensure successful project completion.

Mobile Crane Helpful Links

For more information on crane operations and safety regulations, visit: